Industrial devices — from factory controllers, medical systems, and surveillance cameras to automated testers — require highly reliable memory solutions that can endure extreme environments and long operational cycles.

UMT’s NAND, DRAM, LPDDR, and MCP products are engineered to meet these exacting standards.

1. Industrial Environment Challenges

Temperature extremes, humidity, mechanical vibration

24/7 uptime with minimal downtime

Long maintenance cycles – memory must last years

Data integrity must be maintained under stress

2. Why UMT Memory Fits Industrial Use

✅ Industrial SPI NAND & PPI NAND

Wide temperature range (-40°C to +85°C)

Strong ECC, bad block management

100% tested for endurance and reliability

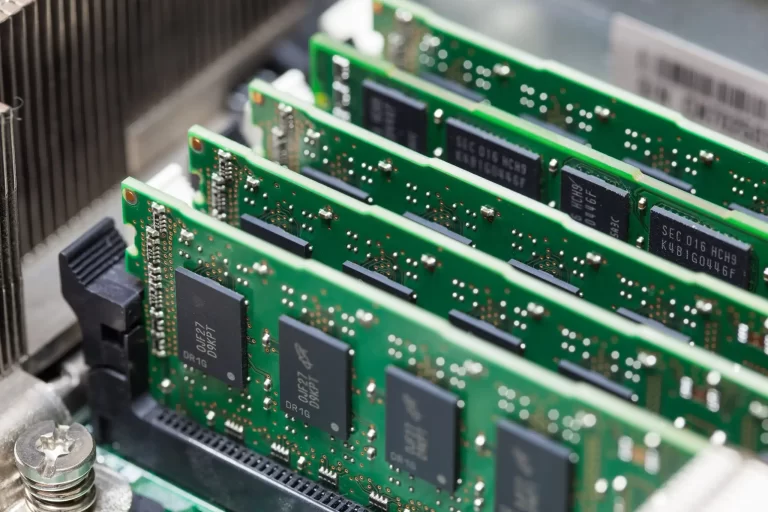

✅ High-performance DRAM & LPDDR

Broad frequency range, industrial-grade variants

Long-term stable operation

Easy to integrate into SoMs and industrial boards

✅ Integrated MCP (NAND + LPDDR)

Space-saving for compact PCBs

Reduces component failure risk

Ideal for smart cameras, medical devices, and POS terminals

3. Real-world Applications

Automated Test Equipment (ATE): Uses SPI NAND + DRAM for fast data logging and high-speed processing.

AI Surveillance Cameras: MCP solutions provide space-saving, power-efficient memory.

Industrial PLC Controllers: UMT NAND supports code storage and log data retention, even during power loss.

Conclusion

In industrial applications, reliability is not optional — it’s essential.

Pionix Vietnam and UMT deliver tailored memory solutions that ensure data integrity, extend device life, and reduce maintenance costs in mission-critical environments.